Towards commercial solar production of sustainable transportation fuels

ETH Zurich, jointly with industrial partners Synhelion, SBB, and AMAG, recently completed a comprehensive technical, economic and environmental analysis of the solar thermochemical production of drop-in fuels.

These synthetic fuels are fully compatible with the existing global transportation infrastructures and can particularly contribute to sustainable aviation, maritime shipping, and certain segments of road and rail transportation. The analysis reveals that carbon-neutral jet fuels can be produced in the near future at competitive costs and achieve a greenhouse gas emission avoidance of over 80%.

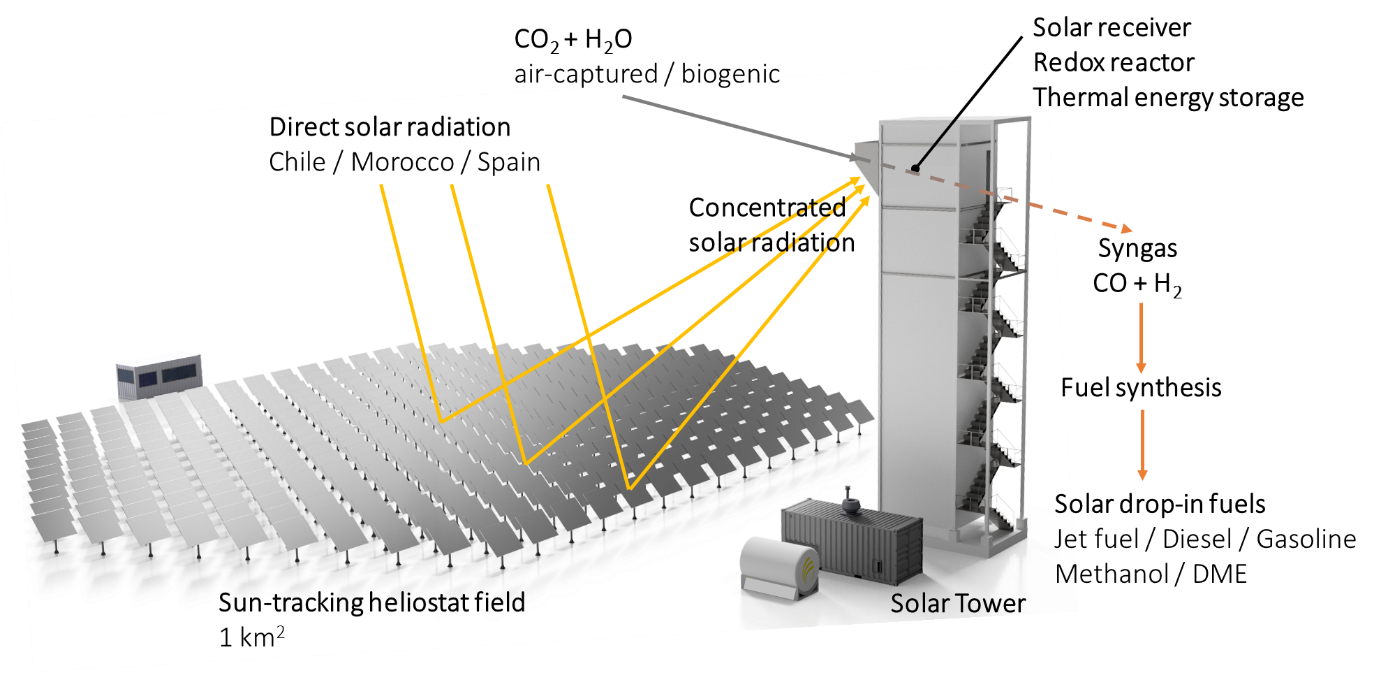

The study was performed within the framework of the project SUNFUELS and funded by the ETH Mobility Initiative. The interdisciplinary team, under the supervision of Prof. Aldo Steinfeld (Renewable Energy Carriers, D-MAVT) and Prof. Anthony Patt (Climate Policy, D-USYS), analyzed the technical performance, costs and life-cycle greenhouse gas (GHG) emissions of the production of various fuels using air-captured water and CO2, and concentrated solar energy as the source of high-temperature process heat. The solar thermochemical fuel production pathway utilizes a ceria-based redox cycle for splitting water and CO2 into syngas ‒ a tailored mixture of H2 and CO – which in turn is converted into liquid hydrocarbon fuels for the transportation sector. The cycle is driven by concentrated solar heat and supplemented by a high-temperature thermal energy storage for round-the-clock continuous operation. The study examines three locations with high direct normal irradiation using a baseline heliostat field reflective area of 1 km2 for the production of six drop-in fuels, namely: jet fuel and diesel via Fischer-Tropsch, methanol, gasoline via methanol, dimethyl ether, and hydrogen.

Two scenarios are considered: the near-term future by the year 2030 and the long-term future beyond 2030.

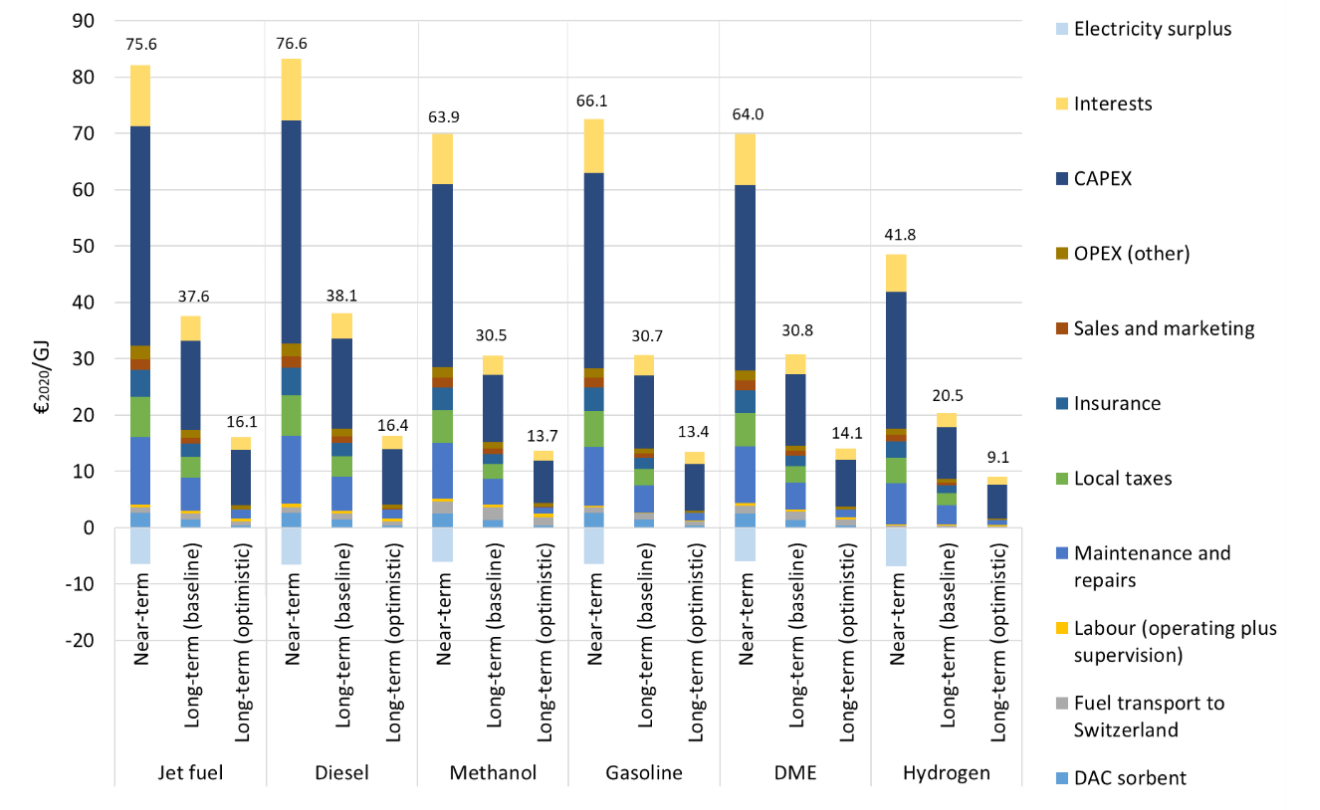

In the near-term future and in regions of high solar irradiation, e.g. Atacama Desert in Chile, the minimum fuel selling price is estimated at around 76 €/GJ (2.5 €/L) for jet fuel and diesel, 65 €/GJ for methanol, gasoline (via methanol) and dimethyl ether (DME), and 42 €/GJ for hydrogen (excluding liquefaction). In the long-term future, with advancements in solar receivers, redox reactors, high-temperature heat recovery and low-temperature direct air capture adsorption, the industrial-scale plant could achieve a solar-to-fuel efficiency of up to 13–19 %, depending on the target fuel, resulting in a minimum fuel selling price of 16–38 €/GJ (0.6–1.3 €/L) for jet fuel and diesel, and 14–32 €/GJ for methanol, gasoline, and DME, making these fuels synthesized from sunlight and air cost-competitive vis-à-vis e-fuels but also vis-à-vis advanced biofuels if optimal conditions materialize.

Additionally, the life cycle assessment shows that GHG savings are already above the EU Renewable Energy Directive II requirement of 70 % for all fuels (relative to fossil fuels) and locations considered, with savings of over 80 % already achievable in the near-term future. Furthermore, the study shows that using a concentrated CO2 source from hard-to-abate industries like steel and cement plants instead of direct air capture for the first solar fuel plants can reduce near-term future costs while still meeting the EU Renewable Energy Directive II GHG reduction requirement. In conclusion, this study demonstrates that solar thermochemical production of drop-in fuels in locations with high direct normal irradiation can become cost-competitive versus e-fuels using PV/wind electricity. In terms of GHG emissions, the LCA of the two pathways gives comparable environmental performances.

The results demonstrate the potential of drop-in transportation fuels from sunlight and air to become a viable option in the future.

Dr. Christian Moretti and Dr. Vikas Patil, co-leading authors of the study comment on the results

“Our study shows the economic viability of establishing an energetically self-sustained, industrial-scale thermochemical redox cycle fuel production system. This innovative system operates around the clock using only air and sunlight, and its feasibility is made possible by resourcefully incorporating thermal energy storage and waste heat recovery at various levels within the plant. Right from the start of the project, we strongly believed in the environmental benefit of this process. We were surprised to discover along the way the significant cost reductions that implementing this design can yield, especially in regions characterized by high direct normal radiation.”

Dr. Moretti looks back to a very positive collaboration with Synhelion, SBB and AMAG during the entire duration of the project. “We held quarterly project meetings and they provided data, technical support and validation with internal knowledge every time possible”. This collaboration has significantly broadened the knowledge on potential production pathways and users for these innovative fuels. Dr. Patil completed his master and doctoral studies at the Renewable Energy Carriers (PREC) group, and subsequently worked on this project during his postdoctoral research. He views this work as a fulfilling conclusion of his studies and research at ETH, and as a natural transition to a new start at Synhelion, which is an ETH spin-off from the same group.

The industrial partners support R&D of sustainable transportation fuels

For AMAG, synthetic fuels can be a solution to decarbonize mobility - in addition to the switch to electromobility. The company is focusing on collaboration with Switzerland's leading universities to jointly address the challenges of mobility and energy supply. Dino Graf, AMAG’s Head of Corporate Communications, is convinced that synthetic fuels will not be simply a transitional but a fully-fledged solution to move transport away from fossil fuels:

“The road to a competitive synfuel is still long, economies of scale are needed, and in the short and medium term, distribution separate from conventional fuels is not expedient - as it is time-consuming and cost-intensive. That is why we are continuing to work with Synhelion on this issue to develop attractive climate-neutral offers for our customers in Switzerland.”

Dino Graf appreciated the high level of professionalism of the project team. “We were involved in the whole process and could contribute where necessary. I am already looking forward to another upcoming project on the topic of electromobility and synthetic fuels.“

For Philipp Haudenschild, the technical specialist for alternative propulsion and fuels at SBB's Energy Storage Competence Centre, the findings of the study are very valuable for industry, “SBB can build up these latest results in its assessment basis for technology scouting and as an important technical source for the re-evaluation and supplementation of the decarbonisation strategy. We will be able to supplement our technology roadmap for applications that are currently still powered by fossil diesel.” states Philipp Haudenschild and acknowledges the excellent exchange with the experts from ETH Zurich and the project team: «Personally, it was a very pleasant collaboration with everyone involved, and it also helped me to develop professionally. This kind of research project helps SBB to better meet the challenges of the future”.

Dr. Philipp Furler, CEO of Synhelion, says: “While Synhelion pursues thermochemical reforming as our go-to-market pathway for fuel production, the thermochemical redox pathway analyzed in this study has a deep connection to Synhelion's origins at ETH. This study brings out this pathway's potential as we demonstrate and further scale up key technologies common to both pathways. This project was a great opportunity to work at the intersection of fundamental research, techno-economics, public policy and market demand for carbon-neutral transportation fuels.”

-

Anthony Patt - Climate Policy, ETH Zurich -

Christian Moretti - Climate Policy, ETH Zurich -

Aldo Steinfeld - Renewable Energy Carriers, ETH Zurich -

Vikas Patil - Synhelion (former PREC, ETH Zurich) -

Philipp Furler - Synhelion -

Dino Graf - AMAG -

Philipp Haudenschild - SBB's Energy Storage Competence Centre

Moretti C., Patil V., Falter C., Geissbühler L., Patt A., Steinfeld A., “Technical, economic and environmental analysis of solar thermochemical production of drop-in fuels”, Science of the Total Environment, Vol. 901, pp. 166005 (1 to 16), 2023. external page https://doi.org/10.1016/j.scitotenv.2023.166005.