INTERACT – Deep learning algorithms for improved predictive railway wheel maintenance

Railway wheels are safety-critical components that significantly impact performance and they are major cost drivers for maintenance. The condition of the wheels also influences the infrastructure. Furthermore, wheel defects cause noise and vibration emissions, impacting the environment and they significantly reduce customer comfort.

Due to their critical nature, wheels are closely monitored by various condition monitoring devices, including fixed installations, wayside monitoring devices, and in-workshop inspections. While wheel defect detection with wayside monitoring devices based on strain gauges is state-of-the-art, predicting wheel deterioration and defect evolution over time under varying operating conditions is still not possible with current tools and knowledge, posing an open research question. Furthermore, predictive deterioration detection based on accelerometer sensors or multimodal approaches has not yet been evaluated under real operating conditions.

In this project, we developed and tested a new methodology based on deep learning algorithms. This methodology enables the training of adaptable and generalizable fault detection and diagnostics models, along with a universal health indicator to monitor evolution over time.

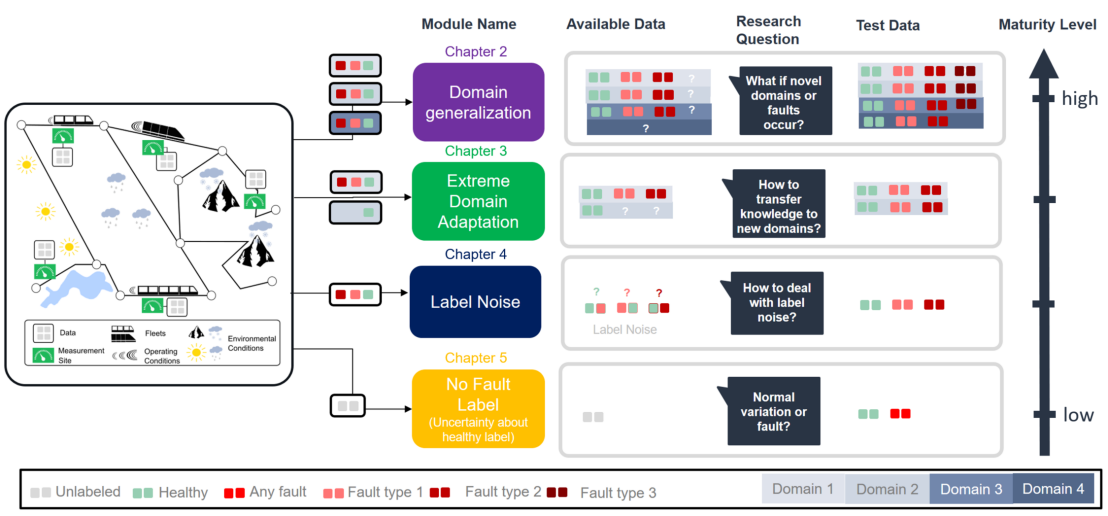

The work addresses key challenges hindering the application of data-driven methods to condition monitoring, such as domain generalization and domain adaptation under label space discrepancies. The main practical and methodological contributions of the project are:

Enabling robust fault diagnostics

One of the significant practical challenges in adopting Machine Learning (ML) methods is label noise, which can severely impact the performance of fault diagnostics ML models. We've developed a framework capable of identifying anomalies, including mislabeled samples. In a subsequent step, the training dataset is modified based on the identified anomalies. This modification enables achieving good classification performance despite label noise, which is common in condition monitoring datasets.

Enabling generation of unseen faults for adaptation to new operational contexts or fleets

In safety-critical systems, faults occur very rarely. Therefore, fault data is typically only available if an asset has been in operation for an extended period. However, in practice, it's crucial to quickly adapt fault diagnostics models to new operational contexts or new fleets (new domains). We've developed a generative model that produces physically plausible faults of a specific type and severity in new domains where the fault hasn't been observed before. The synthetic fault data from the proposed generative algorithm is then used to transfer fault diagnostics models from one domain to another, where certain faults haven't occurred yet. This, in turn, allows for reliable fault diagnostics in new operational contexts.

Enabling fault detection and diagnostics in changing operating conditions and novel fault types

In practice, available condition monitoring datasets are neither fully representative of the operating conditions nor all health conditions. Therefore, a reliable condition monitoring algorithm needs to be robust to changes in operating conditions (fault diagnostics under changing conditions) while remaining sensitive to the emergence of new health conditions (fault detection). We achieve both of these objectives with contrastive feature learning. Contrastive feature learning is an existing type of feature learning typically applied in supervised settings. This work marked the first application of this method to condition monitoring data. The resulting solution is robust to data changes caused by changing operating conditions, avoiding false alarms, and simultaneously sensitive to data changes caused by the emergence of novel faults, enabling safe operations. In other words, it allows for a more efficient and reliable condition monitoring solution.

Learning informative health indicators in an unsupervised setup

Monitoring the health evolution of industrial assets over time is crucial. However, acquiring a continuously labelled training dataset with the current health state of the asset is practically impossible. We've developed an approach to learn an informative health indicator trained in an unsupervised manner that remains robust towards variations in the operational context. This enables the monitoring of an asset’s health evolution over time.

Katarina Rombach worked on this project under the supervision of Professor Olga Fink while completing her dissertation at ETH Zurich. She acknowledges that the collaboration with SBB has given her the unique opportunity to truly understand the process of how the wheel is maintained. She visited the measurement sites and the workshop. This information enabled her to comprehend the potential data sources for the project.

Furthermore, SBB experts collaborated on labelling one test dataset by hand, despite the challenges of defining the severity of defects. This collaboration allowed the team to prepare the test dataset for evaluating deep learning algorithms on real condition monitoring data recorded under real operation.

Typically, benchmark datasets used in research are recorded under controlled environments that differ from real operating conditions. Acquiring real datasets for evaluation was crucial to bridge the gap between research and the industry's requirements.

When asked about the more challenging aspect of her work, she comments on the mismatch between the academic timeline compared to the time that was required to acquire an appropriate dataset including a test dataset with verified labels. As railway wheels are not monitored continuously, gathering reliable labels for evaluation was quite time consuming. It is challenging to complete such a project in a typical PhD.

Stefan Koller and Wilfried Bürzle from SBB closely supported this research project. For SBB passenger transport, transitioning from reactive to proactive wheelset maintenance is a key focus, with current prediction models emphasizing wear and tear. Simultaneously, SBB infrastructure is enhancing wayside measurement technologies, exploring new data-driven services, and developing business areas. This Mobility Initiative project aligns with ongoing internal projects and lays the foundation for advanced defect detection and classification algorithms.

“We learned the significance of close collaboration among stakeholders, recognizing that data collection and the business context are critical aspects for achieving optimal results. The ETH Mobility Initiative provided an excellent opportunity to bring innovation to the railway industry.”SBB Team

-

Stefan Koller - Head of Wayside Train Monitoring Systems (SBB) -

Wilfried Bürzle - Senior engineer, digital transformation and predictive maintenance (SBB)

The results showcased the potential, limitations, and requirements of Machine Learning models in a railway context where wheelset defects are rare and obtaining sufficient samples takes time. The research addressed challenges of limited dataset size and uncertainty from human labeling, providing insights for effective defect detection.

Furthermore, the project emphasizes the importance of not only detecting and modeling damage based on data but also fostering a physical-causal understanding of defect initiation. This understanding enables defining appropriate actions and mitigations.